Did you know nearly half of all deck failures are due to bad joist detailing? This risk is why we at Consac focus on precision. We aim to avoid costly mistakes from the start.

We offer CAD and BIM services globally. Our work includes Joist and Deck Detailing, Sheet Metal Design, and more. We create detailed construction plans and test them to ensure they work.

Our team uses advanced software carefully. We follow strict rules about fees, timelines, and who owns what. We also work to make learning engineering fun and easy for everyone.

This article covers the basics and advanced tips for joist and deck work. It includes choosing materials, following codes, and keeping things in good shape. It shows how Consac uses BIM to improve deck detailing services.

Want to start a project or need detailed plans? Email us at info@consac.com. We’re excited to help create lasting solutions.

Understanding Joists: The Backbone of Deck Structure

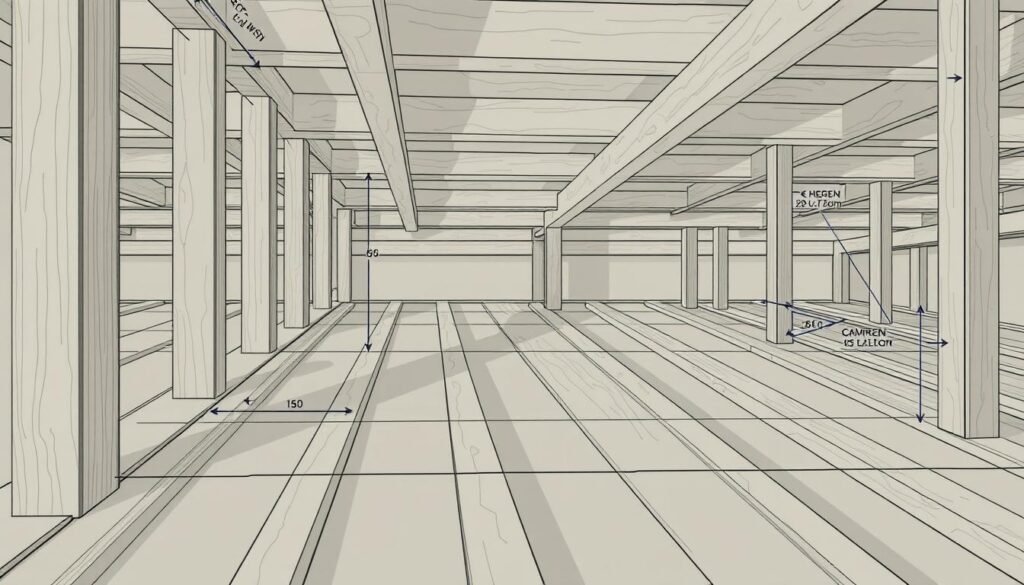

Joists are key in deck building, carrying loads to beams and foundations. They help control how floors feel and move. Choosing the right joists is vital for a strong and comfortable deck.

What are Joists and Their Functions?

Joists support decking boards and handle loads. They also resist bending and shear. This makes floors feel solid and smooth.

Load paths are important. They go from decking to beams and foundations. Making sure connections work well is key.

Types of Joists Used in Decking

There are many joist types, like solid wood, engineered LVL, and steel. Each has its own strengths and uses.

Wood joists are common for their cost and simplicity. Engineered LVLs can span longer and are straighter. Steel joists are great for long spans and thin profiles.

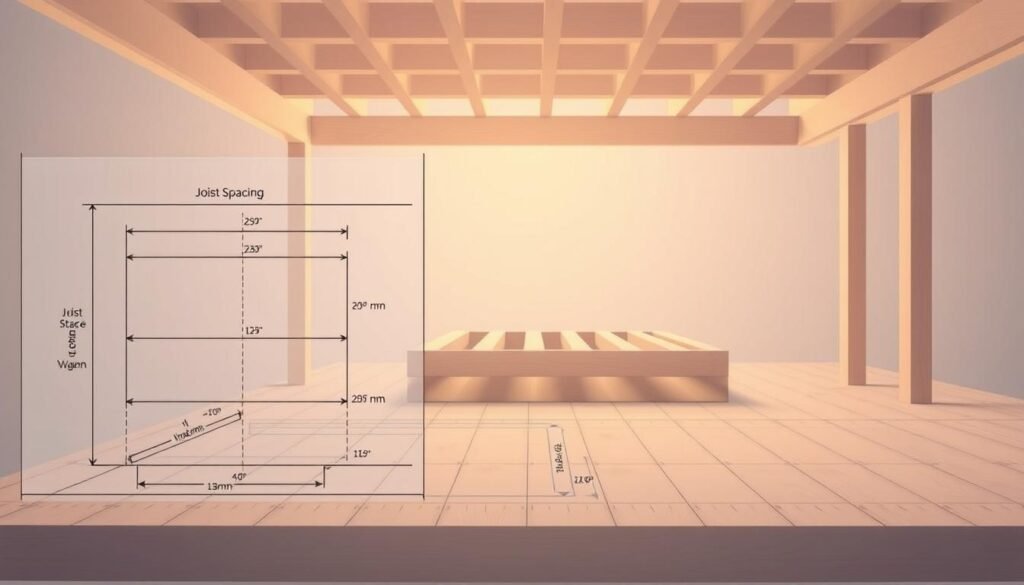

Key Considerations for Joist Sizing

Choosing the right size depends on span, loads, and how much it can bend. We aim for a smooth feel.

Spacing is usually 12″, 16″, or 24″ apart. How they connect to the deck is also important. This affects how well the deck lasts.

At Consac, we use advanced methods to design decks. We focus on strength, comfort, and cost. This ensures our joist choices are the best for the job.

The Importance of Deck Detailing in Construction

We see deck detailing as a link between design and real-world construction. It provides detailed plans for installers. This includes how to connect parts, use fasteners, and ensure waterproofing.

What is deck detailing?

Deck detailing involves CAD and BIM work. It outlines how parts connect, like ledger types and bolt patterns. It also covers flashing, waterproofing, and the order of installation.

These drawings specify material grades and fasteners for different climates. They ensure that construction plans are followed accurately.

The role of detailing in durability and safety

Accurate details prevent common problems like rot and moisture issues. We make sure ledger attachments and flashing are correct. This keeps the deck safe and dry.

Good detailing helps installers meet code and performance standards. It also ensures joists and decking last longer by preventing decay.

Our BIM approach helps catch problems early. It aligns waterproofing with structure and standardizes detailing services. We also test for sound and vibration when needed.

Selecting the Right Materials for Joists and Decks

We focus on how material choices affect performance, cost, and upkeep in deck building. A clear selection process helps avoid surprises on site. Factors like span needs, stiffness, moisture resistance, and local corrosion classes guide our decisions. We use BIM to model material behavior and validate choices with load and vibration simulations.

Common Material Options for Joists

In India, solid sawn timber like pressure-treated pine is often used for framing due to its cost-effectiveness. It’s easy to cut and widely available.

Engineered wood products like LVL and glulam offer longer spans and consistent performance. They help reduce deflection and vibrations, making them suitable for lighter decking systems.

Light-gauge steel joists and open-web steel provide non-combustible framing and long clear spans. Steel is ideal for commercial-grade residential deck construction where fire safety is a concern.

Composite engineered joists are used in high-performance systems. They resist moisture and termites and pair well with low-maintenance decking finishes.

Comparing Wood vs. Composite Decking

Wood species like pressure-treated pine, cedar, and redwood offer natural warmth and familiar textures. While they may have a lower upfront cost, they require regular upkeep. Without proper detailing and ventilation, wood is susceptible to rot and insect damage.

Composite decking, on the other hand, requires less maintenance and resists splintering. It may need closer joist spacing or specific fasteners, and thermal expansion affects fastening rules. The initial cost is higher, but long-term maintenance is lower.

The choice between wood and composite decking depends on span capability, stiffness, durability against moisture and termites, and compatibility with joist type. For example, composites fitted to steel or LVL joists can create robust decks with lower long-term upkeep.

| Attribute | Pressure-Treated Wood | LVL / Glulam | Light-Gauge Steel | Composite Joists |

|---|---|---|---|---|

| Span Capability | Moderate for short spans | High for long spans | Very high for long spans | High, product-dependent |

| Stiffness / Deflection | Lower stiffness, more deflection | High stiffness, controlled deflection | High stiffness, minimal deflection | Engineered for consistent stiffness |

| Durability (Moisture / Termites) | Vulnerable without treatment | Improved resistance with coatings | Excellent, non-combustible | Very good, low degradation |

| Corrosion / Fastener Needs | Standard hot-dip fasteners | Stainless/galvanized recommended | Special self-drilling/anti-corrosion | Manufacturer-specific fasteners |

| Maintenance | Regular sealing, inspections | Periodic checks, less frequent seal | Minimal, inspect connections | Low, clean and check joints |

| Cost (Initial) | Low to moderate | Moderate to high | High | High |

| Best Use | Traditional, budget projects | Long spans, engineered systems | Fire-sensitive, long-span decks | High-performance, low-maintenance decks |

We recommend choosing materials based on India’s climate and corrosion classes. Use the right joist hangers, ledger details, and fasteners for your selection. Apply deck design tips early: match decking to joist stiffness, plan ventilation, and set joist spacing for the chosen material.

In practice, our teams test scenarios in BIM, coordinate connection details, and run vibration checks. This approach ensures predictable outcomes during construction and delivers durable, efficient decks aligned with practical design tips.

Innovative Joist and Deck Design Techniques

We explore ways to mix structural science with beauty. Our methods include mechanical tweaks and digital workflows. This helps teams meet both performance and design goals.

Advanced Engineering Practices

We use multi-criteria optimization to balance several factors. This includes structural strength, sound transmission, impact resistance, and natural frequency. We start by adjusting joist depth, spacing, and material to avoid bad resonance.

Vibration-isolating connections and damping layers cut down energy transfer at key points. Composite floor systems with resilient layers also help reduce impact noise. This is done without losing load capacity or adding too much depth.

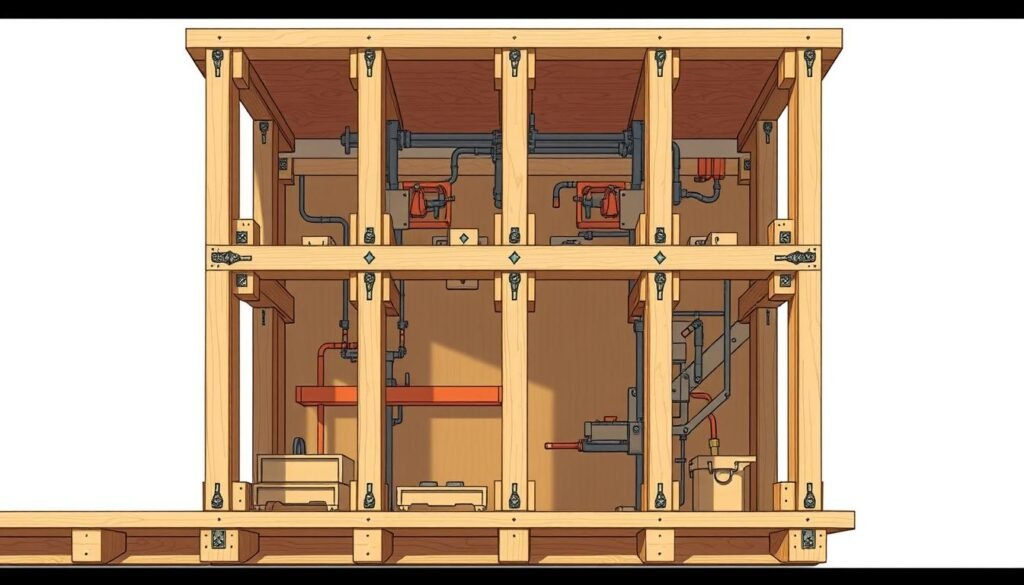

BIM and simulation are key to our work. Three-dimensional models show where sound and vibrations travel early on. Clash detection makes sure details fit with MEP and architecture before we start building, saving time.

Integrating Aesthetics with Functionality

We design with hidden fasteners and exposed timber in mind. Our detailed plans make visible parts last longer while keeping things looking clean.

Deck board patterns match joist layout for a nice visual flow. We place railings and lights carefully to avoid stress and keep the floor looking good.

For installing joist hangers, we plan everything out in shop drawings. This cuts down on mistakes and ensures quality in both performance and finish.

Consac offers BIM-integrated detailing and shop drawings ready for fabrication. We test our designs in homes and high-rise buildings. This checks if they meet acoustic and structural standards while keeping the look.

Building Codes and Standards for Joists

We help design teams navigate through the complex rules for joist design and deck building. Our method combines technical expertise with clear documentation. This ensures plans meet national and local standards.

Overview of National Building Codes

Engineers need to follow national building codes for structural design and more. In India, the National Building Code of India (NBC) is key for floor framing and deck loadings.

We use code clauses to figure out live loads, dead loads, and combination factors. Our work includes structural calculations. These verify joist spacing and deflection limits as required by codes.

Local Codes and Regulations to Consider

Local rules add to the mix with by-laws on fire resistance and more. Designers should check these rules early. Permit approvals depend on following these rules.

Compliance items include guardrail heights and how to attach ledgers. Also, acceptable fasteners and corrosion classes are important. Permit packages need deck plans, connection details, and CAD/BIM drawings for quick approval.

Our contracts follow Consac’s Terms and Conditions. These cover fees, timelines, confidentiality, liability, and who owns intellectual property. The company is based in Norway, but clients in India need to agree on terms that fit their project needs.

Tools and Technology for Precise Joist Placement

We use a mix of traditional tools and modern technology to place joists accurately. This method saves time, reduces waste, and ensures consistent floor framing on every project.

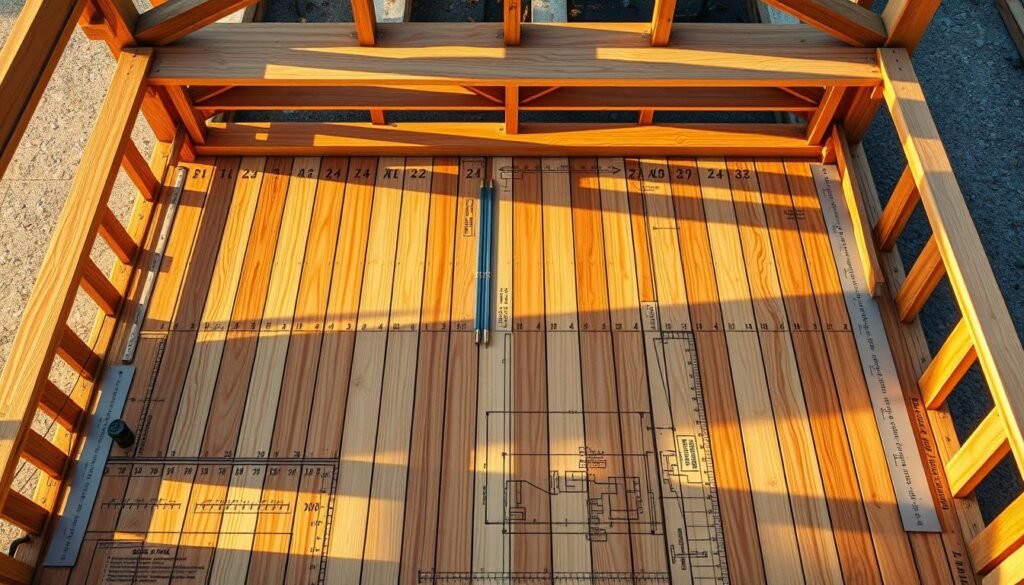

Key tools for measuring include laser levels, digital inclinometers, and tape measures. We also use joist layout templates and calibrated straightedges. These tools help us set the right spacing and alignment before attaching joist hangers or ledgers.

For fastening, we rely on torque-controlled power drivers and corrosion-resistant fasteners. Galvanized joist hangers and jigging fixtures help us place joists consistently. On-site, we use a chalk line, circular saw, and bubble level. We follow the manufacturer’s instructions for hanger nails and wood treatment.

Essential Tools for Accurate Measurements

We start by setting a level datum with a laser level and checking the fall with a digital inclinometer. Then, we mark lines with a chalk reel and verify them with a straightedge. This method helps us avoid mistakes in installing joist hangers and attaching ledgers.

For cantilevers and overhangs, we check the limits carefully. The maximum safe cantilever is one-quarter of the joist length. We also make sure to respect the joist width ratios. Field templates and scrap lumber are very helpful for trial fits before final fastening.

Software Solutions for Design Layouts

We use CAD and BIM platforms to create construction deck plans and shop drawings. These plans are used for prefabrication or on-site work. The software helps us detect clashes, coordinate structural connections, and manage material lists.

BIM-integrated detailing allows us to simulate vibrations and model acoustics. This is useful for predicting ATC/IIC ratings and optimizing joist spacing. Digital workflows reduce rework by verifying performance before starting construction.

| Capability | Tool Type | Key Benefit |

|---|---|---|

| Leveling and alignment | Laser levels, inclinometers | Repeatable datum for joist layout |

| Fastening control | Torque drivers, corrosion-resistant kits | Consistent connection performance |

| Layout and templates | Chalk reels, straightedges, jigs | Faster marking and fewer measurement errors |

| Digital analysis | CAD, BIM, vibration software | Optimized joist sizing and acoustic performance |

We combine practical tools with BIM-integrated detailing to ensure our designs are ready for construction. For more information on joist sizes and spacing, check out this practical guide.

Using these tools and software solutions helps teams achieve consistent results. This approach reduces schedule risks, validates performance, and improves coordination among stakeholders.

Common Mistakes in Joist and Deck Detailing

We often see the same mistakes in joist and deck detailing. Small errors in joist layout, ledger fixes, hanger choices, and ventilation can lead to big problems. We provide practical checks to help teams avoid these issues and extend the life of decks in India’s varied climates.

Avoiding Over-Spacing Joists

Specifying wider spans than allowed can cause decks to sag and boards to fail. Composite boards from brands like Trex or Fiberon have specific joist limits. We check these limits against live-load requirements before finalizing layouts.

Over-spacing joists makes decks vibrate more and fasteners wear out faster. To avoid this, use project-specific calculations, refer to span tables, and confirm with suppliers. BIM clash checks help spot incorrect spacing early.

Ensuring Proper Ventilation Under Decks

Poor ventilation under decks traps moisture and causes rot. We plan ventilation gaps, drainage paths, and airflow routes to prevent stagnant pockets. In coastal or monsoon-prone zones, use corrosion-resistant materials for longer life.

Consider local strategies: install breathable membranes, provide drainage channels, and separate wood from masonry with an air gap. Coordination with MEP reduces unintended penetrations that block ventilation under decks and cause moisture accumulation.

Reliable Deck Ledger Attachment and Joist Hanger Installation

Ledger attachment errors are common: undersized fasteners, missing flashing, or failure to confirm the host structure’s capacity. We dimension ledger details to code and include flashing and through-bolts where required. Shop drawings must show the exact fastener schedule for review.

Incorrect joist hanger installation undermines connections. Choose the right hanger type for load and orientation, follow nailing schedules, and torque through-bolts to manufacturer values. Routine field checks during framing catch installation mistakes before decking proceeds.

Coordination and BIM-Driven Detailing

Many failures trace to poor coordination. MEP penetrations, acoustic bridging, and missing isolation details emerge when teams work in silos. Our BIM-integrated detailing flags clashes, enforces joist hanger installation patterns, and ensures deck ledger attachment details match structural capacity.

We recommend a linked review process: structural engineer, supplier, and contractor sign off on critical details. This reduces site queries and ensures the built deck performs as designed in India’s diverse climates.

Maintenance Tips for Long-Lasting Decks

We offer practical advice to make decks last longer in Indian climates. Regular care saves money and keeps decks safe. Here are steps for checking and caring for decks seasonally.

Routine inspections for joists are key, done at least twice a year and after bad weather. Start by checking ledger connections for rust, movement, or separation. Then, look at joist hangers and fasteners for rust or looseness.

Check joist ends and bearing points for rot, insect damage, or settlement. Also, check deck board condition and spacing to spot moisture traps early.

Use a checklist during each visit to document findings. Keep as-built drawings and inspection notes together. Consac supplies CAD/BIM documents and can recommend fixes based on those records. Replacing damaged joists or hangers early prevents bigger problems.

Seasonal care varies by region. In rainy areas, clear drainage paths and remove debris that holds moisture. After heavy rains, inspect flashings and sealants for breaches. In dry seasons, watch for cracks and warping from thermal stress. In humid coastal zones, use corrosion-resistant fasteners and check for surface salt buildup often.

Preventive maintenance saves time. Reapply protective finishes for timber decks following the manufacturer’s guidance. For composite boards, confirm proper fastening and allow for thermal movement. Replace any split or loose boards as soon as you find them to keep the decking strong.

| Task | Frequency | Key Checks | Why it matters |

|---|---|---|---|

| Ledger and house connection | Biannual + after storms | Corrosion, gap, flashing condition | Prevents deck separation and water ingress |

| Joist hangers & fasteners | Biannual | Rust, looseness, missing screws | Maintains load transfer and safety |

| Joist ends & bearings | Biannual | Rot, settlement, insect damage | Averts structural failure |

| Deck boards | Seasonal | Cracks, warping, spacing, fastenings | Preserves walking surface and drainage |

| Flashings & sealants | After heavy rain / yearly | Cracks, detachment, seal integrity | Stops moisture entry into framing |

| Protective finishes | Per manufacturer (1–3 years) | Peeling, wear, UV damage | Extends wood life and appearance |

| Documentation | Ongoing | As-built plans, inspection reports | Guides repairs and retrofit planning |

We suggest pairing routine inspections with documented service records. This helps with targeted repairs and keeps warranties valid. Good upkeep follows best practices in deck construction and keeps structures safe for years.

Why Choose Consac for Your Joist and Deck Projects

We combine practical experience with engineering innovation for every project. Our Consac joist and deck detailing services are BIM-integrated. This means we use global CAD capabilities to reduce site rework.

We design with several criteria in mind. These include structural integrity, acoustic performance, and vibration control. We then test our designs in the field to ensure they meet our standards.

Our Expertise in Joist and Deck Detailing

We offer fabrication-ready documentation and construction deck plans. These help speed up permitting and meet local deck building codes. Our designs are optimized for clarity and fewer surprises on-site.

Our service delivery is on time and follows agreed specifications. We protect client confidentiality and manage intellectual property under contract. Liability limits are also stated in our service agreement.

Client Testimonials and Success Stories

Clients see faster approvals and better construction outcomes. Our approach often cuts down on rework and improves sound and vibration. These success stories show real benefits like shorter approval times and fewer issues.

For consultations, proposals, or to request our services, contact us at info@consac.com.