Nearly 70% of construction rework comes from coordination errors. This shows why Structural Design Innovation is key today.

At Consac Engineers, we mix engineering skill with creative problem-solving. We aim to bring cutting-edge structural design and advanced architectural solutions to India. Our goal is to make complex ideas easy for everyone to understand.

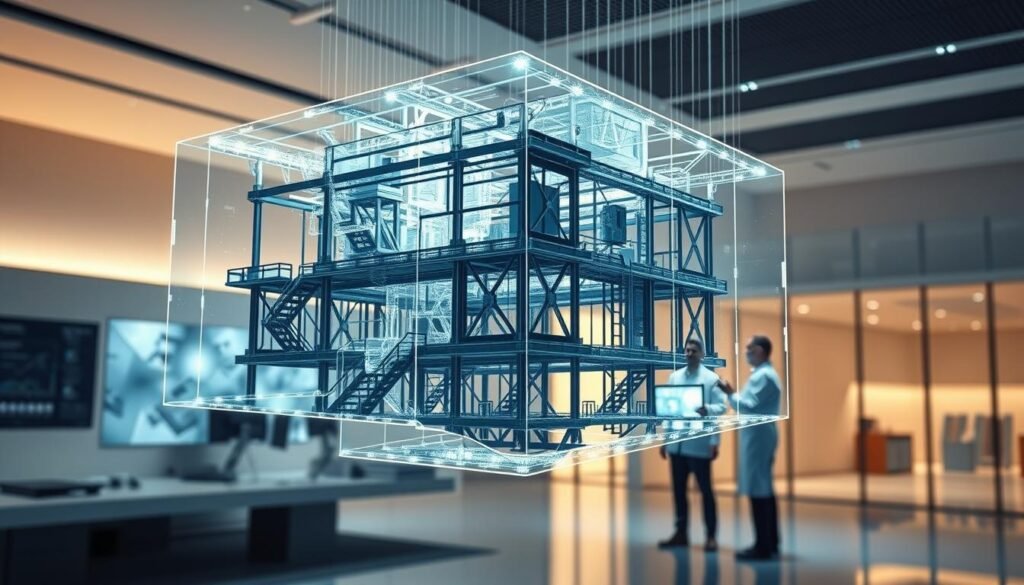

We focus on structural BIM services. This digital approach uses data for every part of the structure. It helps with accurate load calculations, clear views, and finding problems early. This reduces mistakes, cuts costs, and speeds up projects.

Our main skills are in structural analysis, clash detection, and creating detailed plans. We also offer on-site support. This leads to better teamwork and safer, smarter results for everyone involved.

Want to start a project or work together? Contact us at info@consac.com.

Understanding Structural Design Innovation

We look into how Structural Design Innovation changes architectural engineering and construction. New materials, digital tools, and methods have moved design from simple sketches to detailed models. These models guide decisions, aiming for safer, faster projects with better performance over time.

What is Structural Design Innovation?

Structural Design Innovation uses new ideas, advanced materials, digital workflows, and creative construction methods. It aims to improve safety, performance, and looks. It includes Structural BIM and AI-enhanced BIM, which are smart 3D models that hold all the project details.

AI-powered BIM adds smart analytics, clash detection, and schedule optimization. These features turn static drawings into active project partners. They spot risks and suggest changes before construction starts.

Historical Context and Evolution

Design used to rely on 2D drafting and paper trails. This method led to fragmented documentation and slow progress. The move to 3D BIM brought a single source of truth and faster coordination among teams.

Digital tools have made feedback loops shorter. What took weeks now takes hours. This change reduces risk by catching conflicts early. It connects design, fabrication, and construction workflows, marking a step towards futuristic engineering.

Importance in Modern Engineering

Today’s projects face tough codes, sustainability rules, and pressure to save time and money. Modern technologies help meet these challenges without losing quality. Structural BIM supports detailed analysis and coordination, aligning with stricter rules.

Embracing these innovations prepares firms for changing codes and sustainability goals. It streamlines workflows, reducing change orders and improving handoffs during construction and maintenance.

| Aspect | Traditional Approach | Innovative Practice |

|---|---|---|

| Design documentation | 2D drawings, separate files | Integrated Structural BIM with embedded data |

| Coordination | Manual clash checks, delayed detection | AI-enhanced clash detection and automated reports |

| Schedule control | Static Gantt charts, manual updates | Model-driven schedule/resource optimization |

| Risk management | Reactive solutions on site | Predictive analytics and early mitigation |

| Materials and methods | Conventional selections, limited data | Advanced materials, data-informed selection using modern building technologies |

Key Principles of Structural Design

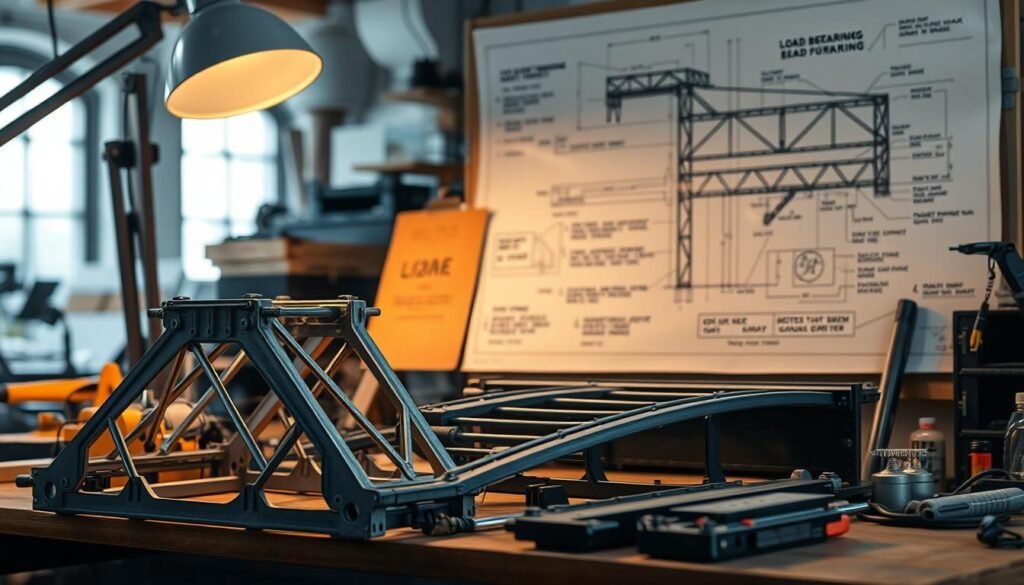

We start with the basics of every project: how loads move, where forces gather, and how to lower risks. Clear paths and the right support elements make structures reliable. This guide focuses on practical rules and steps used in India.

Load paths and primary supports

Understanding how forces move from roof to foundation is key. Beams, columns, posts, and footings form the main path. In multi-span decks, as spans grow, so do the sizes of joists and beams. Cantilevers should not exceed 1/4 of the joist span to avoid too much deflection.

Connections are more important than many think. Many failures start at joints. So, it’s vital to use the right fasteners and detail plates, welds, or bolts. We check the load path, confirm member capacity, and verify connection strength during design.

Design choices that improve performance

Balanced spans often work better than irregular ones. Symmetry helps spread loads evenly, reducing stresses and making construction simpler. For complex shapes, we consult engineers early and use clash detection to find issues before starting work.

Choosing the right materials is key to structure and maintenance. We compare steel, reinforced concrete, and engineered timber by strength, durability, and load behavior. Using less material while keeping safety high can save costs.

Safety, codes, and digital verification

Following safety rules and codes is essential. We must follow local Indian rules and document load calculations for inspectors. Structural BIM helps create accurate load calculations and aligned documentation for code checks.

Using BIM and optimization tools early reduces changes and risks on site. This approach shortens schedules, improves structure life, and aids in maintenance planning. It also supports new construction methods by making prefabrication and modular assemblies predictable.

Practical methods to reduce risk

Adding redundancy helps structures withstand unexpected damage. Doing structural analysis shows internal stresses and checks for equilibrium. This ensures the sum of forces is zero in stable designs.

We suggest documenting safety margins, load paths, and connection details clearly for inspectors and contractors. For more on foundational principles and modern practices, see this overview: key principles of structural engineering.

- Load-bearing mechanics: trace and size members; limit cantilevers to 1/4 span rule.

- Safety standards and compliance: document loads, follow local codes, use BIM for validation.

- Structural design innovation: optimize sections and layouts to reduce material use while keeping safety margins.

- Innovative construction techniques: use prefabrication and modular design to control quality and lower site risk.

Advanced Technologies in Structural Engineering

We look at how digital tools and new materials change design and building projects. Our goal is to see how software and materials science work together. They help create new architectural solutions in India’s building sector.

Role of software in design

Structural BIM is key in today’s design work. It makes 3D digital models with structural data for planning and checking. AI-powered BIM helps find and fix problems before construction starts.

AI can suggest new designs and improve member sizes. It also helps with cost and resource planning. These tools make planning faster and reduce errors.

Machine learning connects sensor data and simulations to predict maintenance needs. For more on AI in building systems, check out this article on AI in MEP engineering.

Importance of materials science

New materials let engineers design better: like high-performance concrete and composite systems. We choose materials for strength, but also for how easy they are to build with and how long they last.

BIM models include details for fabricators and erectors. This helps in making accurate plans. Using the latest materials in models improves how buildings perform and last over time.

By combining software analysis with material databases, we can make buildings better. This mix supports modern building technologies and sustainable choices throughout a project’s life.

| Capability | Software Benefit | Materials Impact |

|---|---|---|

| Clash detection | Automated identification of spatial conflicts via AI-powered BIM | Reduces rework through accurate connection and reinforcement data |

| Cost forecasting | Real-time cost analysis linked to schedule and quantities | Material choices influence lifecycle cost and embodied carbon |

| Design optimization | Generative design offers multiple alternatives quickly | Enables lighter, stronger solutions with composites or engineered timber |

| Performance simulation | Integrated models test structural, thermal, and energy behaviors | Material-specific inputs yield accurate lifecycle and energy assessments |

| Maintenance prediction | Sensor data feeds ML models for predictive maintenance | Material durability data refines replacement schedules and costs |

Case Studies of Innovative Structures

![]()

We share case studies that show how Structural BIM helps projects from start to finish. These examples highlight how creative ideas meet real-world challenges. This is done through a clear process: understanding needs, creating detailed models, finding clashes, optimizing, and ongoing support.

We focus on creating detailed models with all the necessary details. We also analyze and optimize these models for load performance. This helps construction teams by providing clear plans and reducing confusion on site.

Iconic Buildings and Their Design Processes

For projects like the Mumbai International Finance Centre, we start with a detailed analysis. This captures both the design goals and the practical limits early on.

Next, we develop detailed models with all the structural elements. Engineers then check these models for performance, making adjustments as needed. This ensures the structure meets all requirements.

Clash detection comes after that. It finds any problems with how things fit together. Solving these issues in the model makes the construction phase smoother and improves teamwork.

Lessons Learned from Engineering Challenges

Early clash detection is key. It helps avoid surprises and reduces the need for costly changes later. We also document load calculations carefully. This makes it easier to get approvals and verify the work.

Getting the details right, like how connections are made, is also important. This clarity helps everyone involved. Strategic planning and analysis help use materials wisely without sacrificing performance.

These case studies show better teamwork and fewer surprises on site. Using BIM leads to lower costs, fewer mistakes, and faster completion times for complex projects.

Sustainability in Structural Design

We focus on making projects sustainable at every stage. Our method combines new design ideas with goals for carbon, durability, and cost. This way, we build strong, green buildings that meet India’s rules and people’s desire for eco-friendly spaces.

Eco-Friendly Materials

We start with materials that are good for the planet. We use engineered timber, recycled steel, and low-carbon concrete. These choices cut down on carbon emissions without losing strength.

BIM helps us pick the best materials. It shows us things like weight, heat, carbon, and how often they need to be fixed. This lets us find the best mix to lower environmental harm.

Energy Efficiency Considerations

The way a building is laid out affects how much energy it uses. We think about how the sun hits it, how it keeps cool, and how it fits with the outside. This helps cut down on energy use in warm places like India.

We use BIM to test how well a building works before it’s built. We check things like light, heat, and air flow. This helps us make buildings that use less energy overall.

We make sure sustainability is part of the design from the start. We set goals, choose materials, and use BIM to show we’re meeting green standards. This makes the building process more efficient and helps the environment.

In the long run, this means less carbon, less upkeep, and more chances for incentives. By combining new design ideas with green materials and energy use, we make buildings that last and are good for the planet.

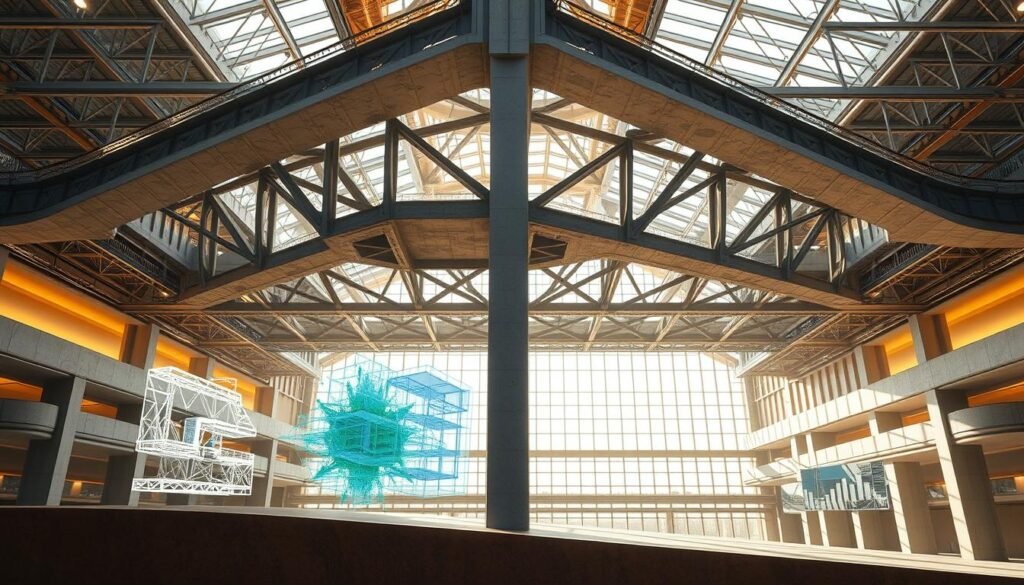

Collaborating with Other Disciplines

We focus on clear workflows that bring design teams together early. By using structural BIM as a single source of truth, architects and engineers can align intent and constraints in one intelligent model. This approach supports advanced architectural solutions while keeping schedules realistic.

Integrating Architecture with Engineering

We run joint sessions where architects from firms like Foster + Partners and engineering teams work in the same model. This shared environment reduces rework and lets creative design concepts stay true to buildable details.

Our process sets file standards, naming rules, and coordinate systems so models sync cleanly across Revit and Tekla. Teams trade clear exports and annotated views instead of ambiguous PDFs.

Prioritizing Interdisciplinary Communication

We adopt proactive protocols: early clash detection, daily issue logs, and centralized documentation. These steps cut RFIs and avoid late-stage revisions that push up costs.

AI-BIM tools flag conflicts and suggest fixes automatically. When a clash is detected between a beam and an MEP run, the system proposes alternative routing and notifies the responsible discipline.

Practical steps we follow include scheduled coordination reviews, cross-disciplinary requirements analysis, and shared naming conventions. These practices improve constructability and smooth the transition to site execution.

| Practice | What It Fixes | Expected Outcome |

|---|---|---|

| Single-source structural BIM | Model divergence between teams | Fewer errors in shop drawings; better alignment with creative design concepts |

| Early clash detection | Late-stage rework and delays | Reduced RFIs; faster approvals |

| Common file standards | Incompatible exports and lost data | Smoother handoffs between Revit, Tekla, and MEP tools |

| Regular coordination reviews | Misunderstood requirements | Improved constructability and clearer on-site instructions |

| AI-BIM assistance | Manual issue tracking | Automated suggestions for advanced architectural solutions and faster resolution |

The Future of Structural Design

We are at a critical moment. New trends and technologies are changing how we design and build structures. Our teams believe that tools will soon be more than just helpers. They will analyze risks, suggest changes, and improve delivery in real time.

Emerging Trends and Technologies

AI is making BIM smarter in construction. It uses machine learning to spot problems early and predict costs. This lets engineers focus more on design.

Prefabrication and modular construction are getting better thanks to digital models. New materials and lifecycle modeling are helping meet sustainability goals.

Predictions for the Next Decade

We see digital models becoming smarter partners. They will predict delays, suggest solutions, and manage resources better. Off-site fabrication will grow as design data improves.

Structural design will include sustainability by default. It will use advanced materials and data to meet strict standards. Firms that use these tools will work faster, safer, and cheaper.

Roles will change to focus on data and teamwork. We suggest keeping skills up to date and adopting new technologies early. This will help you stay ahead in India’s growing construction market.

Safety and Risk Management

We aim to cut down surprises on site and make structures last longer. Our method combines new design ideas with strict steps. This way, teams can find and fix problems early, keeping projects on time and within budget.

Assessing Structural Risks

We use BIM to simulate loads and test how structures might fail. It spots conflicts before materials are even brought to the site. AI uses past data to predict where problems might happen, based on soil, wind, and seismic activity in India.

Every site’s unique challenges are added to the model. We track every load calculation and keep records for managing risks over a structure’s life. This makes it easy to check and improve risk assessments.

Implementing Effective Solutions

We focus on strengthening weak spots, often connections. We choose strong materials and careful details: high-strength bolts, precise welds, and extra paths for loads. Following codes and documenting calculations helps everyone involved.

On-site monitoring keeps things running smoothly: sensors, regular checks, and AI alerts for any issues. Model-based planning cuts down on mistakes in ordering materials. These steps make solving problems clear, measurable, and reliable.

Results include fewer surprises, safer buildings, and less maintenance over time. By combining safety, risk management, and design innovation, we turn risks into reliable performance.

Education and Training in Structural Engineering

We aim to update education and training to keep up with new practices. Advances in software, materials, and methods require learning that matches real-world needs. This section offers steps to enhance skills, confidence, and leadership in structural design.

Importance of Ongoing Learning

Staying current with Structural BIM, AI tools, and new materials is essential. Short courses and labs help practice skills like model development and clash detection. Regular training boosts quality and promotes sustainable construction.

Certifications and Hands‑on Opportunities

Seek out certification programs like BIM credentials and Autodesk Revit courses. These certifications prove your skills and increase job chances in India’s construction sector. Workshops and webinars keep you updated, while vendor bootcamps turn theory into practice.

Practical guidance

- Make training relevant by using real project workflows, from start to finish.

- Use team assignments to mimic real-world projects, combining architectural engineering and structural teams.

- Focus on analysis, risk assessment, and material selection to support innovative structural design.

| Learning Path | Duration | Core Focus | Outcome |

|---|---|---|---|

| Foundations in Structural BIM | 6–8 weeks | Modeling, documentation, clash detection | Competent Revit modeling for interdisciplinary teams |

| Advanced AI-BIM Integration | 8–12 weeks | Automation, optimization, data-driven design | Ability to apply AI tools to optimize structural layouts |

| Materials and Sustainable Design | 4–6 weeks | Modern materials, lifecycle analysis, carbon reduction | Informed material choices that support sustainability goals |

| Professional Certification Track | Varies (module-based) | Exam-ready review, project portfolio, ethics | Industry certification that enhances career mobility |

We promote ongoing growth: combine classroom learning with site visits, mentorship, and team projects. This approach links certifications with real project results, creating leaders in structural design innovation across India.

Innovations at Consac Engineers

We mix technical know-how with creative ideas to boost structural design. Our team uses BIM services, AI, and materials science to create models. These models are detailed, sustainable, and ready for construction.

Unique Projects and Achievements

Consac Engineers has worked on projects that use new architectural solutions and materials. We help from the start to the end of a project. This approach cuts down on mistakes and makes sure designs can be built exactly as planned.

Client Success Stories of Structural Design

Clients see many benefits, like fewer mistakes, saving money, and faster work. They also get better coordination among teams. Our BIM services and clash detection help make decisions quicker and lower risks.

To talk about working together, training, or questions, email us at info@consac.com. We aim to help engineers, students, and teachers design better, safer buildings in India.